Small wind power

What is small wind power?

Small wind turbines are, as their name suggests, smaller in capacity than wind turbines for industrial production. Most small wind turbines are a few hundred or a thousand watts (kW), which can be installed near a summer cottage or property. Small wind turbines of up to 50-100 kW used in agriculture and small industry are also considered small wind turbines.

Power plant types

There are many types of small wind turbines: the most common are the horizontal axis propeller type and the vertical axis Savonius and Darrieus type. Horizontal-axis turbines are easier to implement with the largest possible swept area and therefore have a higher energy production potential. Vertical axis wind turbines work well in turbulent wind conditions, which increases the siting potential of vertical axis turbines. However, its generation potential is lower than that of turbines of the propeller type.

Yield and factors affecting it

The wind conditions (wind speed, prevailing wind direction and vorticity) at the selected site have the greatest influence on the amount of energy produced by the wind turbine. The output is also influenced by the swept area of the propeller, the air density (depending on the temperature) and the technical characteristics of the turbine. An important characteristic is the operating range of the wind turbine, which describes the wind speed where production starts (e.g. 3 m/s) and where production must stop (e.g. 20 m/s).

The swept area is often a clearer benchmark than the rated or maximum power. When comparing power, different power plants should be compared at the same wind speed, for example 5 m/s. A good benchmark is the annual energy yield at the site of use, measured according to IEC 61400-121, if this is specified.

For a small, cottage power plant, the swept area is generally 3-12 square metres, with propeller blades 1-2 metres long. For a detached house, the swept area is at least 20-30 square metres, i.e. the blades of a propeller-type power plant are at least about 3 m long.

Table. Examples of power plants of different sizes and their typical yields.

Source.

| Propeller diameter (m) | Generator size (kW) | Annual production (kWh) |

| 2-3 | 0,2-1 | < 1 000 |

| 3-4 | 1-3 | 1 000-3 000 |

| 4-6 | 3-5 | 3 000-7 000 |

| 6-10 | 5-10 | 7 000-25 000 |

Location and windiness

A wind turbine works best in a location where there is plenty of open, unobstructed space in the prevailing wind direction. Surrounding terrain, trees, buildings, etc. will affect wind power output. They cause the wind to become turbulent, which reduces the output of the wind turbine. Even flat ground causes wind turbulence, which is why wind turbines are usually placed on a mast. The best yield is obtained when the wind blows freely into the turbine from all directions.

The power plant must be high enough to leave a turbulent zone below it. In open conditions (e.g. in the outer archipelago), sufficient production may be achieved with a mast of up to 6 metres. Vertical axis spiral models have a lower turbulence effect than horizontal axis shovel models.

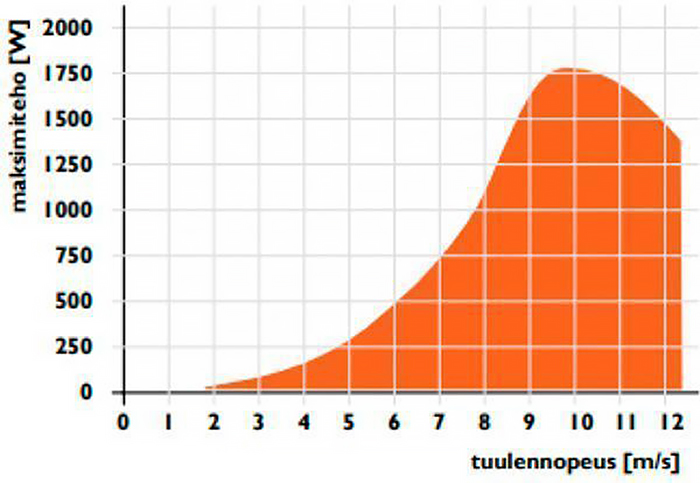

The higher the average wind speed, the better the yield of the wind turbine. As the wind speed increases, the yield of the turbine increases exponentially. A power curve can be plotted for each turbine, showing the power in relation to the wind speed. When interpreting the power curve, pay attention to how much power the plant can produce at the most common wind speeds (4-6 m/s). It is important to verify that the power curve has been measured under real conditions, either by the manufacturer or by an independent third party. The power curve should be found in the technical data of the power plant. If the vendor cannot provide actual measurement data, there is no guarantee that the power curve is accurate.

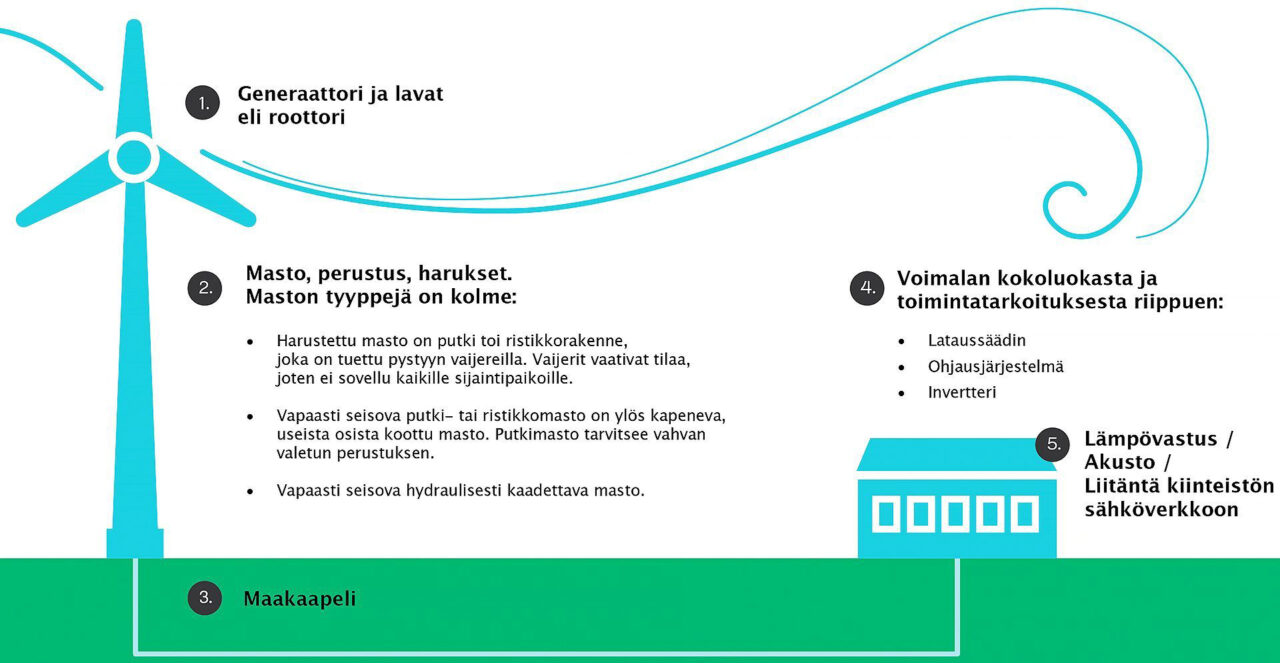

Placement

Will a separate mast be needed or will the power plant be located in an existing building? A separate mast will require about an acre (10 m x 10 m) of space, plus room to raise and lower the mast. There must also be vehicle access to the site. The type and height of the mast and the weight of the wind turbine will affect the foundation required and the space required for any guy wires. The mast must always be free of sway and stable.

When installing in a building, it should be noted that the generator will always cause some resonance and noise disturbance. In the case of propeller-driven power plants, a mast is also required when installed in the building, as the building itself causes turbulence that can hamper production. The best location is at the corner of the building, where the wind is most frequent. The durability and load-bearing capacity of the roof structures and their anchorage possibilities must be carefully studied beforehand.

It must also be ensured that any ice that may come off the blades of the wind turbine does not pose a risk to people or property. It is also important to ensure that the wind turbine is not located so close to a residential property that the shadow of the rotating rotor falls on windows, as this can cause disturbing flicker.

Finding out the wind speed

It is difficult to judge windiness by sense alone. A rough estimate can be made based on location; whether you’re by the sea or a lake, on a hill, in open or wooded terrain. The Finnish Wind Atlas provides wind data from heights of 50-400 metres, too high for a small wind turbine.

The simplest and most reliable way to measure the wind conditions on a site is to install your own anemometer and measure the wind conditions yourself at the intended height and location. Measurements should be taken over a sufficiently long period (6-12 months). You can either buy a wind meter yourself or rent one. A mast is often needed for the measurements, which can be rented from companies selling measuring equipment. There are different types of wind meters, ranging in price from a hundred to a few hundred euros.

Purchase of a small wind turbine

For what purpose is the wind farm being purchased?

The smallest wind turbines are often used in off-grid locations, such as cottages. In these cases, the wind turbine is usually connected to a battery, which is charged by the turbine. The electricity from the battery can be used for all the electricity needs of the property and even to heat the water heater. In addition to the batteries, the system can be connected to solar panels and/or an aggregator, for example.

A small wind turbine can also be used when connected to the grid, usually mainly for its own use and for excess sales. In this case, the wind turbine must be connected to an inverter, which converts the rectified electricity from the turbine into alternating current and ensures the quality of the electricity.

How do I get started?

Choosing and purchasing a wind turbine requires expertise and time. There are not many vendors of small wind turbines in Finland, and finding a suitable supplier can take time, especially if you want turnkey delivery. Together with the vendor, it is a good idea to assess the investment site, the suitability of the type of power plant for the site and the profitability of the investment. The vendor should be able to fully guide the buyer in choosing the right system and in safe and correct operation, monitoring and maintenance.

At least these are things to consider before buying a wind turbine:

- Rough site assessment and its impact on the choice of power plant type

- Local wind conditions

- Whether the power plant will be installed on a separate mast or attached to the property

- What kind of foundations are needed

- Own electricity demand and its impact on the size of the wind turbine fork

- Preliminary report on permit issues

The municipal building inspectorate will clarify:

- Is it possible to locate the wind turbine on the planned site?

- How high can you put the mast (this determines the limits of the implementation)?

- What permits are required (usually at least a building permit)?

- Early contact with the grid company (for grid-connected plants)

- Consider whether to take wind measurements

- Search for a power plant supplier

- Does the vendor’s equipment meet European and Finnish standards?

- Is it possible to see similar equipment on a site that has already been built?

- Will the seller provide installation, user training and maintenance if necessary?

- Finding a reliable and competent electrical contractor

- Ensure adequate internet access, which is needed to monitor consumption data.

Costs

The cost of a small wind turbine varies greatly, depending on the size of the turbine, the type and height of the mast and the terrain work required. In total, a power plant can cost around €5 000 per kW installed.

The costs include:

- The power plant itself (generator, blades) around €1 000/kW.

- The minimum cost of a mast is around €500 (plus the cost of setting it up, which varies considerably depending on the type of mast and the terrain).

- Wind measuring equipment, own or rent. Small wind instruments cost from a hundred euros upwards. A meter mast is also included.

- Foundations and earthworks, the price of which varies greatly depending on the terrain and distances.

- Battery, electrical work, cabling.

Small wind turbine dealers

NOTE! The following list of companies selling small wind turbines is not exhaustive, nor is it a recommended list.

Permitting

Permitting practices vary from municipality to municipality, so the first point of contact for matters relating to permits is the municipal building inspector.According to the new Building Act, which came into force on 1 January 2025, a building permit is required when the mast is at least 30 metres high, and at least in a zoning area, consultation of neighbours is usually required as part of the process. However, practices should always be checked with the municipality before embarking on a project.

The installation of wind turbines is electrical work and always requires the appropriate installation permits. When connecting to and transmitting electricity to the grid, a production grid service contract must be concluded with the local distribution grid company. Depending on the size of the power plant and where it is installed, a separate generation connection contract may also be required.

If a generation facility is connected to a consumption site where a consumption connection contract is already in place, it is usually not necessary to conclude a separate generation connection contract. In addition, before connecting to the grid, a contract must be concluded with the electricity company for the surplus electricity to be sold. A contract may also be concluded with a company other than the one from which the electricity is purchased.

You should check with Traficom if you need an air traffic control permit. There are three maximum heights (10 m, 30 m or 60 m) depending on the proximity of the structure to the runway of the aerodrome, light or alternate aerodrome.

The Defence Forces rarely need permission to build a small wind farm. Individual small wind turbines less than 50 metres high may be built without a permit, provided they are not restricted to areas in permanent use by the Defence Forces.

Elsewhere online:

Small-scale electricity production and electricity storage

General information form for small-scale production and electricity storage

Taxation

Property tax

Small-scale household electricity generating installations that produce electricity mainly for their own use are excluded from property taxation. They are not structures within the meaning of Article 2(2) of the Real Estate Tax Act.

Electricity taxation

The electricity tax liability refers to both the excise duty on electricity and the security of supply levy. The electricity tax is generally levied on network operators and electricity producers, although exemptions apply to small electricity producers.

Small electricity producers are divided into three categories for the purposes of electricity taxation, based on the rated capacity of the electricity production installation and the annual electricity output:

- Electricity produced by microgeneration plants with a rated capacity of up to 100 kWh is exempt from all electricity taxation obligations.

- Small producers of electricity with a rated capacity of more than 100 kWh but not more than 800 000 kWh per year are registered as electricity taxpayers with the Tax Administration. Even these small producers are not required to pay electricity tax, but they submit an annual tax return once a year as a so-called zero tax return, which is used to control the limit of the annual tax-free production.

- An electricity producer who generates electricity with a rated output of more than 100 kVA using electricity generating equipment with an annual production of more than 800 000 kWh submits a normal tax return (taxable and non-taxable supplies) every month, whether or not he feeds electricity into the grid.

Income tax on electricity generation

A small-scale producer who feeds his excess electricity into the grid and receives compensation for it is in principle taxable on the income from it, but in practice small-scale electricity production does not generally have to be declared for tax purposes.

According to the national guidelines issued by the Tax Administration, the income and related expenses from the sale of electricity by a small producer are only declared on the tax return if the sale of electricity is profitable. If there is no taxable income from the sale of electricity, nothing is declared on the tax return. In practice, the annual expenditure and depreciation associated with the sale of electricity by a household is almost invariably so high that the household’s small-scale electricity production does not generate taxable income.

Elsewhere online:

Service and maintenance

A wind turbine, like any other piece of equipment, needs to be maintained regularly. The owner of a wind turbine should carry out a visual inspection of the turbine annually or whenever necessary (for example, after a storm).

Inspections/maintenance include, for example:

- Cleaning the wings

- Greasing of bearings

- Inspection of screw fixings

- Checking the tension of the mast ropes

- Checking the functions of the control unit

More thorough maintenance is required every 5 years or so (see manufacturer’s instructions for details). When purchasing, it is a good idea to consider the need for maintenance and how it will be carried out. The easiest way is to have a service contract with the vendor or to have the vendor organise the service in some other way.

Milja Aarni

Expert